As my company works with Small to Medium Manufacturing companies, it is striking how many of their individual problems fall into the same eight categories. These companies are trying to deal with most, if not all of these pain points simultaneously. We often find that juggling multiple issues leaves management feeling overwhelmed.

These “Pain Points” can be categorized as follows:

- Hiring and maintaining capable workers.

- Technical problem-solving capability.

- Changing customer business requirements.

- Maximizing physical capital utilization.

- Mid-term (3 to 5 years) business uncertainty.

- Financial risks for funding growth.

- Growth of business complexity.

- Business ownership/management transition.

Capable Workers:

Not only is it difficult to hire technically capable people to operate machinery and/or to perform assembly tasks, it is also a challenge to find individuals with the “soft” skills as well. As for what your company can do, find ways to make your workforce more effective, produce more with the same number of employees. Simple automation is one example.

Problem Solving:

The technical skill shortage in the company’s employees usually is realized as an inability to do effective problem solving. If it is quality concerns, cost issues or merely a need for continuous improvement, the lack of problem solving skills is usually realized as an operational performance issue. Reach out for help. An expert can provide an initial push with a sustainable plan for Continuous Improvement.

Customer Requirements:

Many customers are demanding tighter quality requirements and sales price reductions simultaneously. Customers are also expecting more product development and product design to be provided by the manufacturer. To many small manufacturers this is a new business activity that requires expert planning and implementation. Reach out, develop a plan.

Capital Utilization:

Opportunity for growth and financial performance requires the small manufacturer to find ways to improve the performance of the facility, equipment and tooling. Producing more products on the same assets is one methodology to grow the business and improve financial performance simultaneously.

Business Uncertainty/Financial Risks:

Stagnate economic growth, rising health care costs, and volatile sales forecast all contribute to the uncertainty of the small manufacturers’ business. Although numerous signs are indicating manufacturing growth (domestic and export) is on the horizon, the risks are undeniable. Your company must be prepared to respond.

Business Complexity:

Exponential growth and manufacturing complexity have become the norm for most Small to Medium manufacturers, as evidenced by management and employees juggling multiple challenges. The time to address these issues is now. Learn to manage your time more effectively and reach out to experts that know how to simplify today’s manufacturing challenges.

Business Ownership/Management Transition:

Many small businesses today are either owned or operated by a “Baby Boomer”. This demographic is requiring many small manufacturing companies to deal with the issues surrounding the transition to new management or ownership. You must have a plan.

Conclusion:

We are all just multi-tasking jugglers: The most accomplished jugglers have difficulty maintaining more than about 7 to 8 objects in the air at one time. The world record for juggling balls is 11 for 25 catches, yet most small business managers are expected to manage a similar number of issues continuously 24/7.

So what do you do as a small manufacturing company operator?

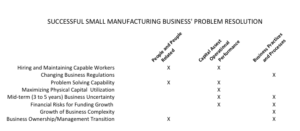

A very effective method that proves successful time and time again is to “bucket” your problems requiring resolution and look for outsourced resources to help improve your company’s capability. The chart below is an example of how to organize challenges for Small Manufacturing Companies into three categories:

- People and People Related

- Capital Assets Operational Performance

- Business Practices and Processes

Bill May is the Founder and President of High Value Manufacturing Consulting. HVMC is based in Tennessee with extensive manufacturing consulting experience, helping to serve small to mid-sized manufacturers. The company’s mission is to provide quick response solutions that net high value manufacturing results.

If you would like more specific information on how to manage your time using buckets, please refer to the article “Time Management in a Bucket: A Creative Way to Manage Your Time”. By Lisa Montanaro.

Did you enjoy this blog? Search our blog library for other topics of interest: https://highvaluemanufacturingconsulting.com/blog/