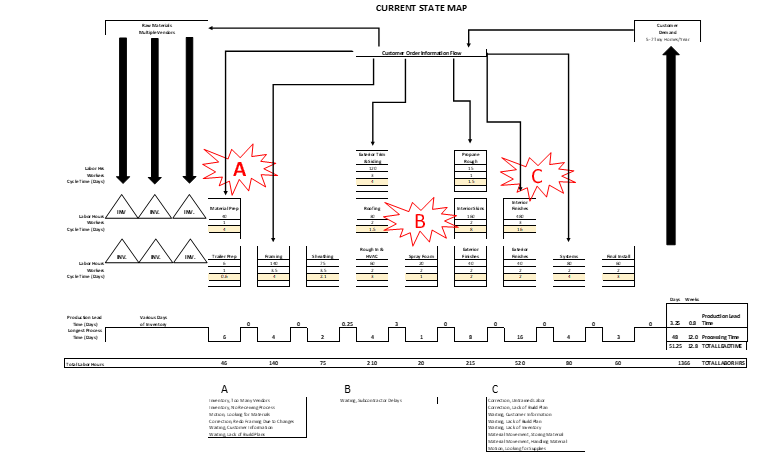

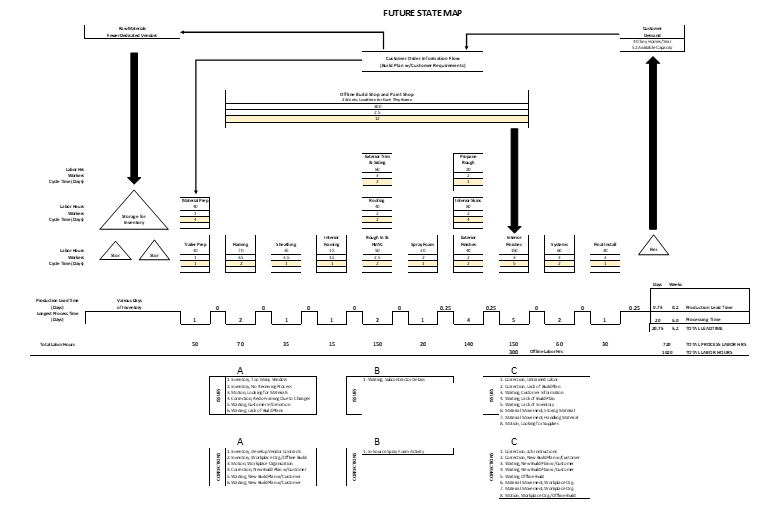

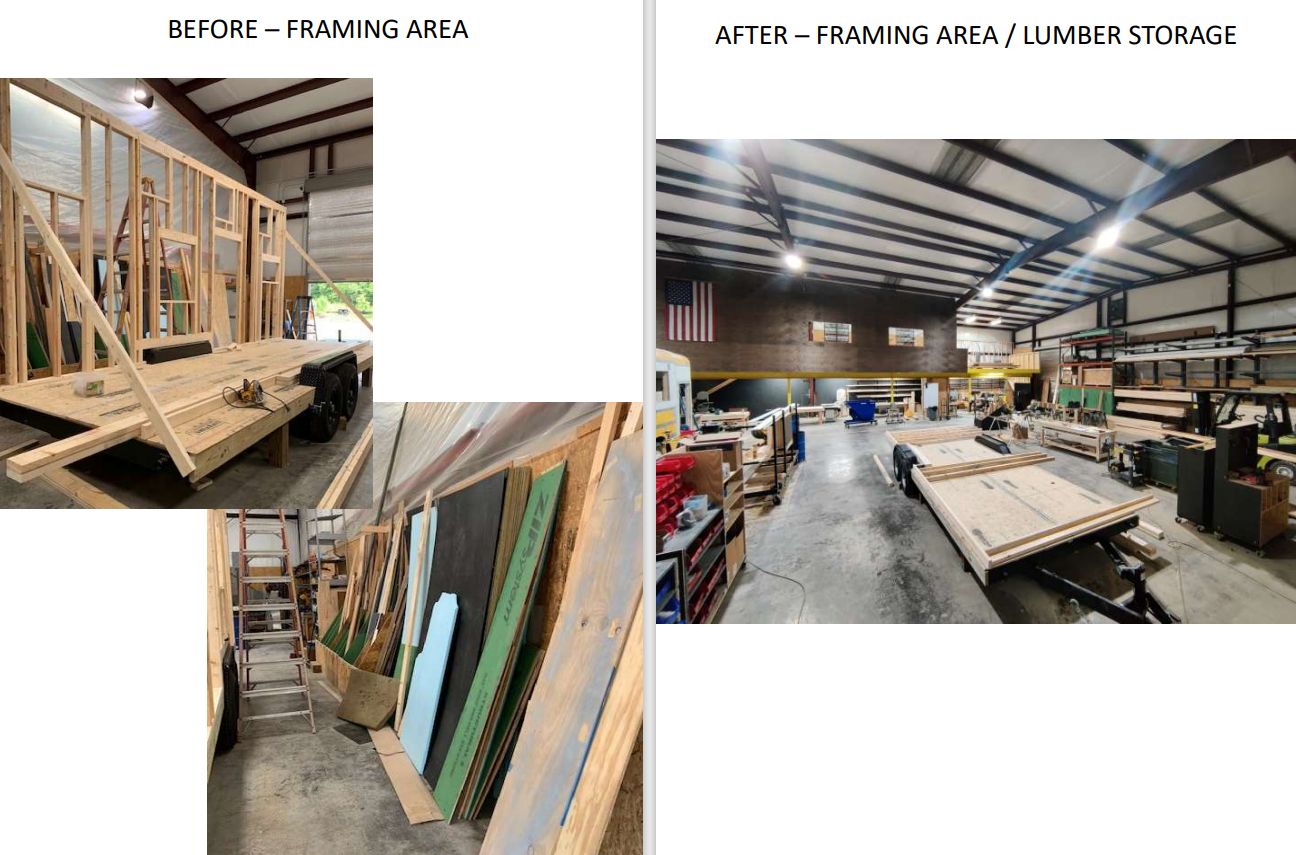

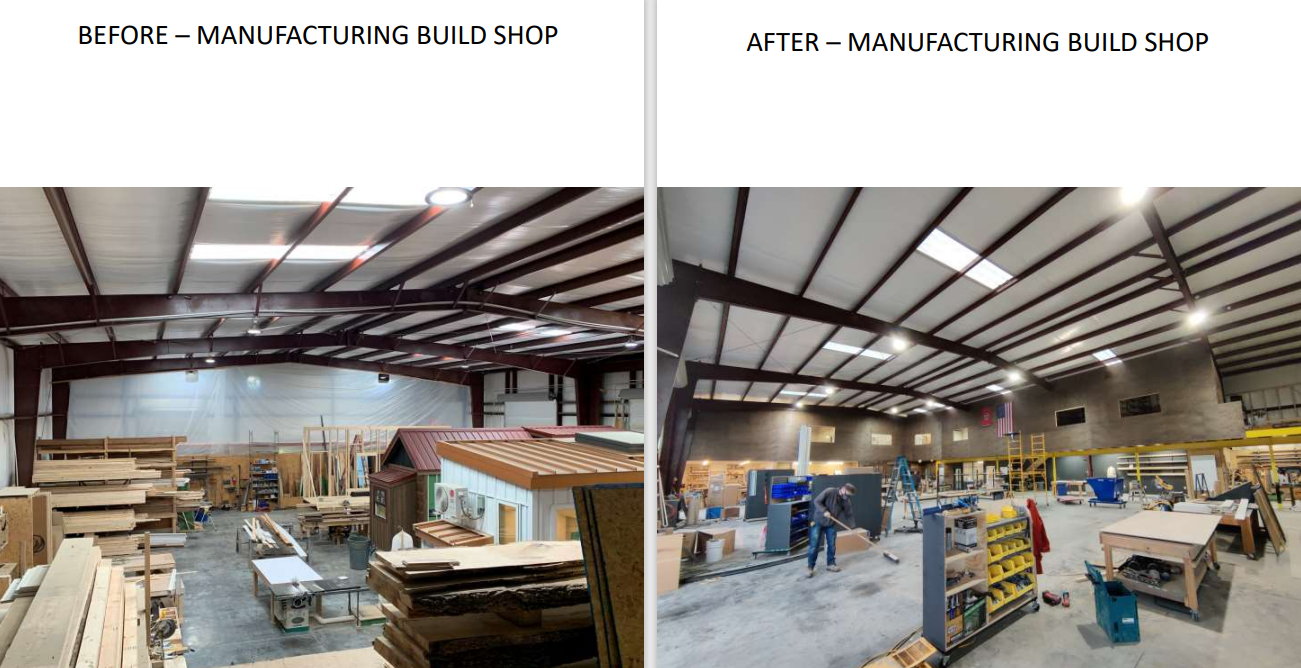

Assignment

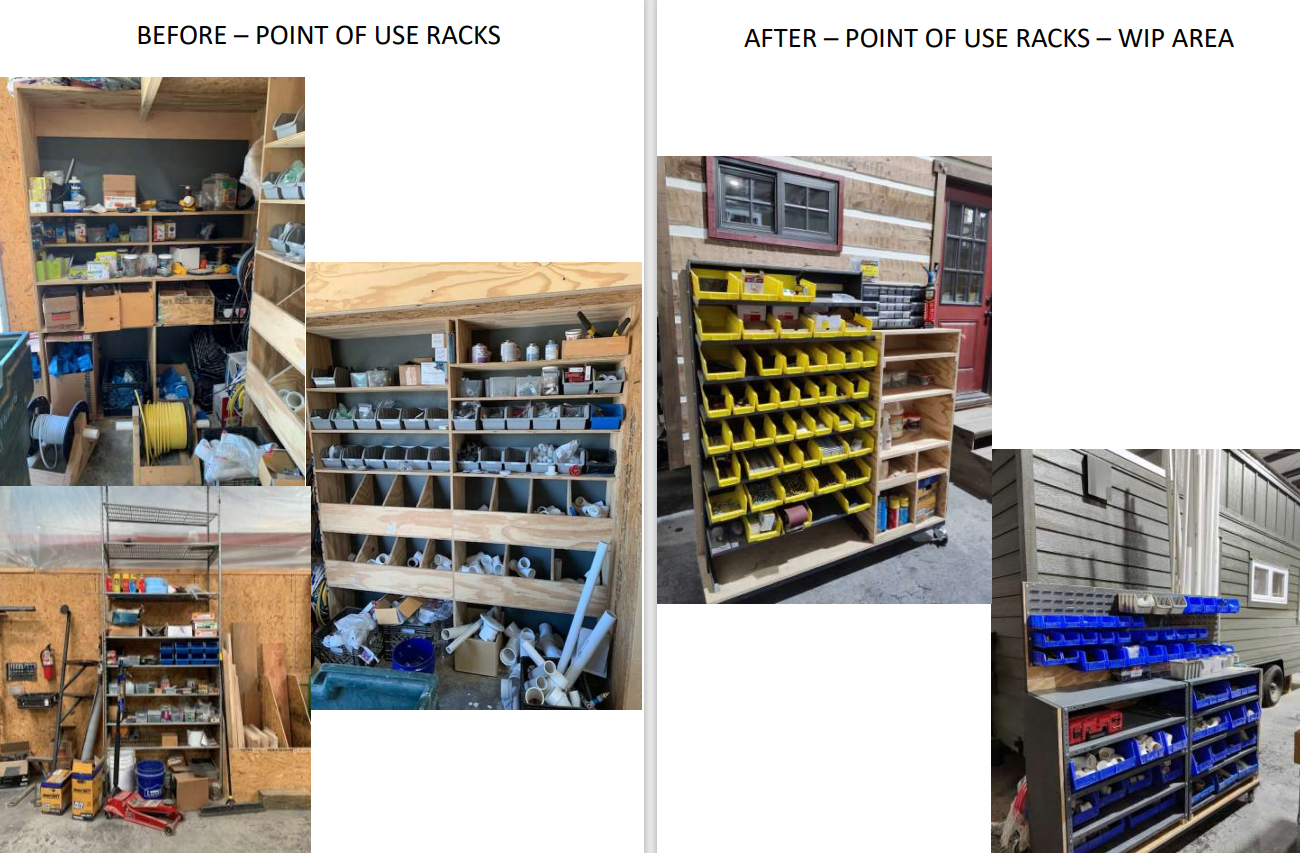

Support modular home manufacturer in plant expansion with a goal to increase production capacity by 250%; Provide highly experience consulting engineers and manager to assist with Value Stream Mapping (VSM) Workshop, implement facility modification project, and establish lean manufacturing concepts.