Assignment

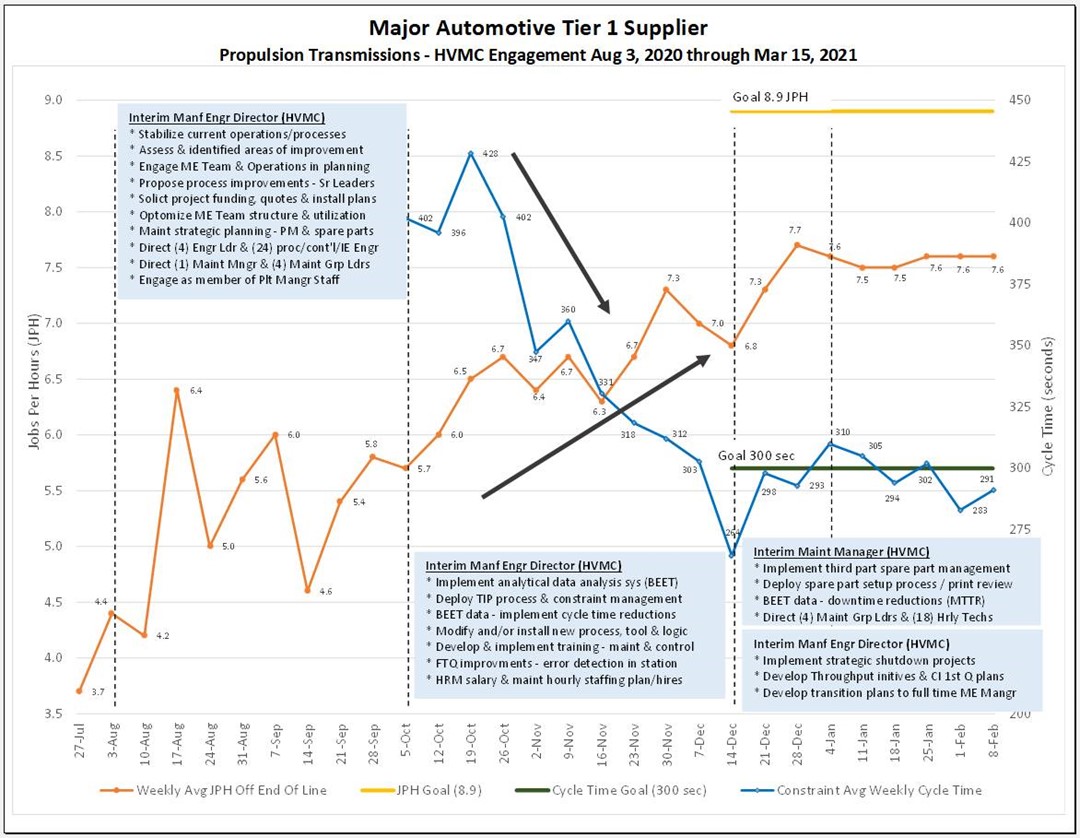

Deploy highly skilled, highly experienced supplemental labor/management resources for a major Tier I North America automotive supplier of propulsion transmissions, during critical and troubled new program launch.

Results included:

- Implemented new constraint management and data analysis system to drive continuous improvement process.

- Developed Tier I’s engineering team and budget; implemented best practice project management processes.

- Improved JPH from 3.7 to 7.5 toward a capability of 10 JPH over a five-month period reaching 80% of capacity.

- Improved constraint equipment cycle time from a weekly high of 428 seconds to on average target rate of 300 seconds.