Assignment

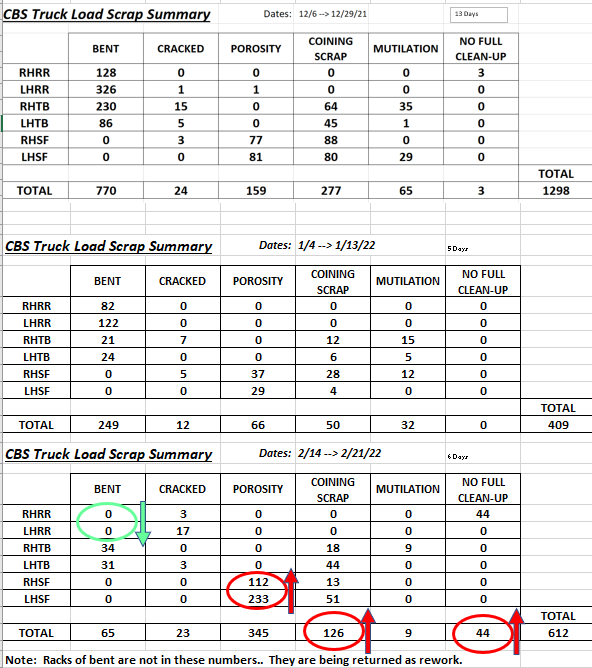

Improve third party performance; identify root causes of defects and reduce scrap in vehicle assembly by major North American automotive manufacturer.

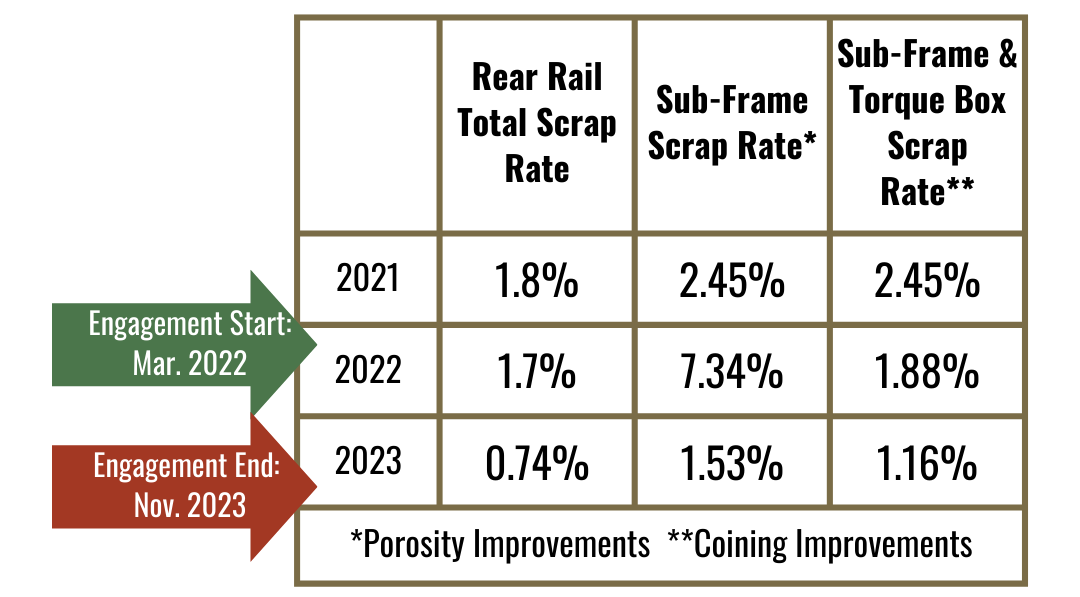

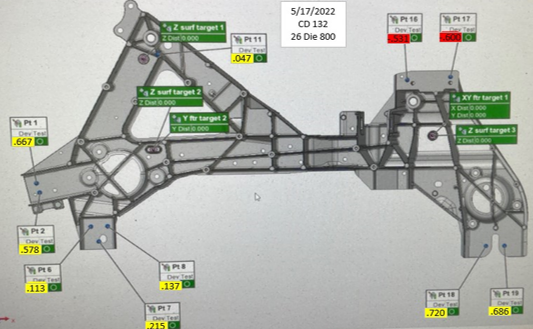

By assessing performance and implementing a data-driven rework process, HVM helped the client to successfully reduce scrap for this vehicle assembly.

- Rear Rail Scrap improvement: 57.7%

- Sub-Frame Scrap improvement: 68.7%

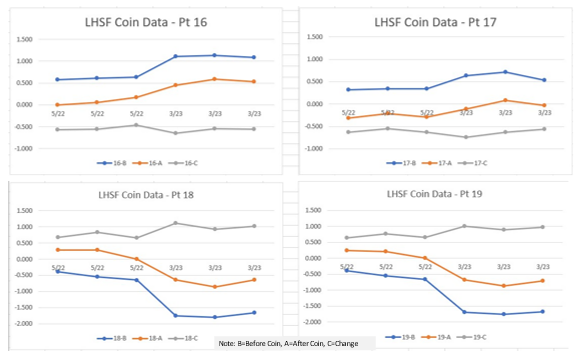

- Sub-Frame & Torque Box Scrap improvement: 46.4%

The development of a detailed coining guideline and scrap data tracking tool during this assignment will continue to support quality and consistency.